CVL Technical Sales will be integrated into our sister brand, PennAir, on December 19 – same team, stronger capabilities.

- Serving Maryland, DC, Virginia, Pennsylvania, & Delaware

- 800-230-4285

CVL Technical Sales will be integrated into our sister brand, PennAir, on December 19 – same team, stronger capabilities.

As colder months approach, the need for efficient process heating systems becomes crucial for industries, universities, government buildings, and other large facilities. Maintaining comfortable temperatures and operational efficiency during the fall and winter is impossible without proper heating systems in place. For those who rely on steam-based systems, steam traps are an essential component to ensure heating processes are running optimally and efficiently.

From manufacturing plants to universities, large-scale facilities depend on process heating to distribute warmth and maintain functionality during colder seasons. In industries where heat is necessary to support production, steam systems provide an effective solution. For buildings like universities or government offices, these systems ensure the environment remains comfortable for occupants and employees alike.

The Fall months are the perfect time to invest in steam traps, which improve both the reliability and efficiency of your steam heating system. Proper maintenance and regular replacement of steam traps save on energy costs and reduce downtime due to system failures.

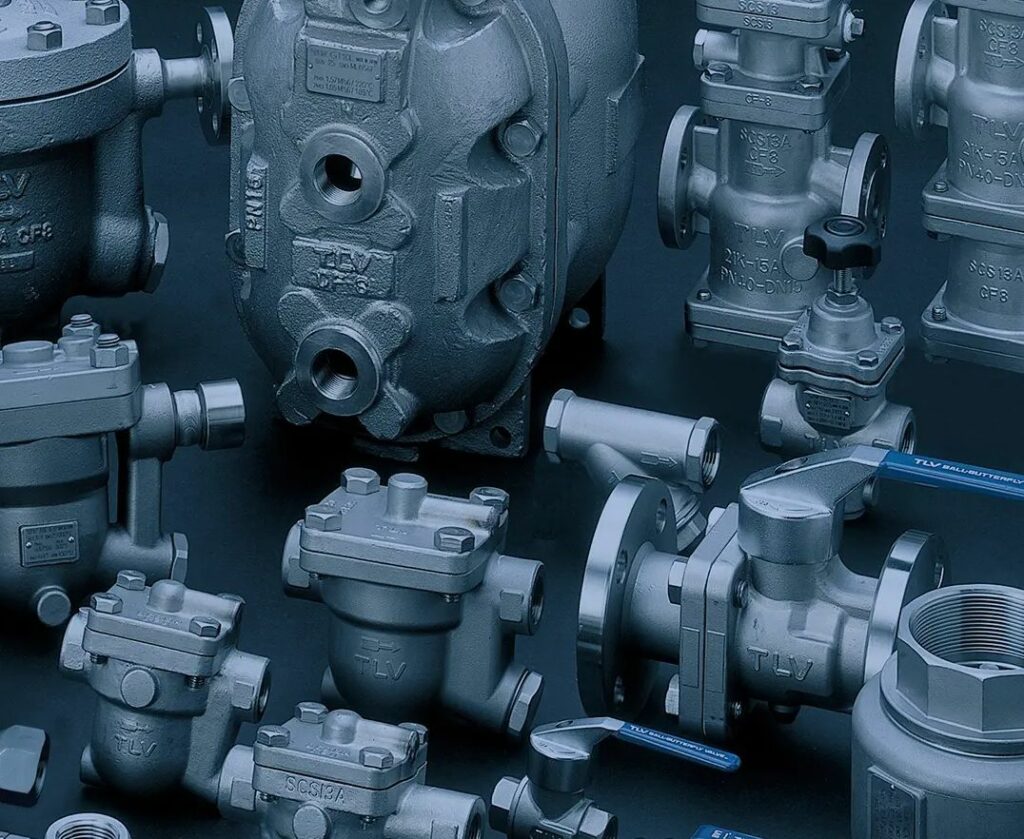

Steam traps are vital to any steam heating system. Their primary function is to discharge condensate, air, and non-condensable gases without letting steam escape. This helps the system maintain its efficiency by preventing heat loss. Efficient steam traps ensure heat is delivered exactly where it’s needed, whether that’s in industrial processes or within large buildings.

Without properly functioning steam traps, systems can lose significant amounts of energy, driving up costs and reducing overall efficiency. Did you know that a single leaking steam trap can cost hundreds, if not thousands, of dollars in energy loss annually?

With the heating season fast approaching, now is the perfect time to inspect, repair, and replace outdated or inefficient steam traps. Doing so saves your facility from costly repairs and unexpected system failures during peak heating demand.

By proactively investing in high-quality steam traps, you’ll see the benefits in reduced energy costs, longer system lifespan, and improved heating reliability. If you wait until a failure happens, not only will repairs be more expensive, but you’ll also experience significant downtime during critical operations.

Aging or faulty steam traps are more common than you might think. Many facilities lose thousands of dollars each year to energy inefficiencies that could be resolved by simply replacing worn-out steam traps. Some common issues include:

According to the U.S. Department of Energy, in some cases, up to 20% of steam traps in large facilities are leaking or malfunctioning, costing the facility significant amounts in wasted energy. Addressing these problems before the colder months set in can make a big difference in energy savings.

When investing in new steam traps, it’s important to choose the right type for your specific application. The most common types of steam traps include:

Consulting with experts like CVL Technical Sales can help you select the most suitable steam traps for your system. We offer tailored solutions, ensuring your steam systems are optimized for efficiency and performance during the winter months.

As fall sets in, take a proactive approach to maintaining your facility’s heating system. By inspecting and investing in efficient steam traps now, you’ll ensure your steam heating systems run smoothly throughout the season, saving on energy costs and preventing costly downtime.

Ready to optimize your process heating system for the winter? Contact CVL Technical Sales today to learn more about how we can help with your steam trap needs. We’re here to provide the expertise and support you need to keep your facility warm, efficient, and reliable.