CVL Technical Sales will be integrated into our sister brand, PennAir, on December 19 – same team, stronger capabilities.

- Serving Maryland, DC, Virginia, Pennsylvania, & Delaware

- 800-230-4285

CVL Technical Sales will be integrated into our sister brand, PennAir, on December 19 – same team, stronger capabilities.

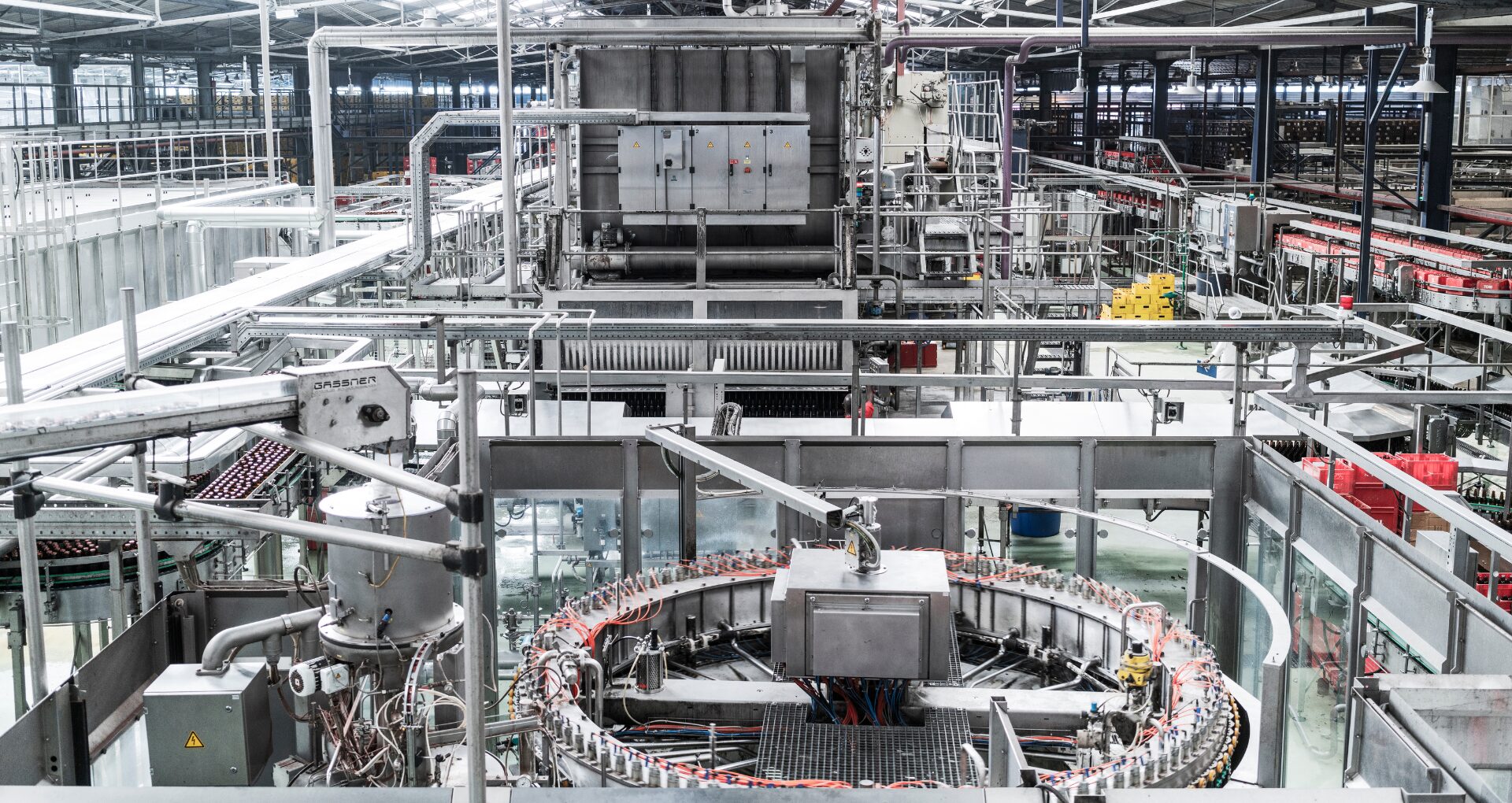

CVL Technical Sales offers a comprehensive range of process instrumentation solutions tailored to meet the diverse needs of various industries. Our expertise spans across sectors such as chemical, pharmaceutical, industrial manufacturing, and water/wastewater treatment, where precise control of temperature, pressure, and flow is crucial for maintaining efficiency, safety, and product quality. As a trusted partner, we provide industry-leading instruments, including temperature sensors, pressure gauges, flow meters, control panels, and control systems, designed to enhance the performance and reliability of your operations. Backed by a commitment to excellence, CVL Technical Sales ensures that your process instrumentation needs are met with the highest standards of precision and reliability.

Don’t see your industry below? No worries, we may be able to still help. Reach out to start a conversation.

Accurate process instrumentation is vital in the chemical industry, ensuring precise control of temperature, pressure, and flow to maintain product quality and safety. From temperature sensors to pressure gauges, these tools are essential for preventing hazardous conditions and optimizing production efficiency.

In the construction industry, process instrumentation supports the safe and efficient operation of HVAC systems, water treatment, and other critical infrastructure. Tools like pressure sensors and flow meters help maintain optimal conditions, ensuring long-term reliability and performance.

Process instrumentation plays a crucial role in the food and beverage industry, maintaining strict hygiene and quality standards. Temperature sensors, level sensors, and pressure gauges are key to ensuring that products are processed at the right conditions, enhancing safety and consistency.

Government and defense facilities benefit from process instrumentation through enhanced environmental monitoring, energy management, and operational safety. Pressure gauges, temperature controllers, and flow meters help ensure safety and regulatory standards.

In hospitals, process instrumentation ensures the maintenance of critical conditions in medical environments. Accurate temperature, pressure, and flow sensors are essential for patient safety, ensuring that medical processes and equipment operate within precise parameters.

Process instrumentation is integral to the HVAC industry, where it ensures the precise control of temperature, humidity, and air quality. Pressure sensors, temperature controllers, and flow meters work together to enhance energy efficiency and occupant comfort in various environments.

In industrial manufacturing, process instrumentation is critical for optimizing production processes and ensuring product consistency. Instruments like flow meters, pressure sensors, and process controllers enable precise control over manufacturing operations, reducing waste and improving efficiency.

The pharmaceutical industry demands the highest levels of precision, where process instrumentation is crucial for maintaining strict temperature, pressure, and flow control. These instruments ensure that pharmaceutical products are manufactured under exact conditions, ensuring efficacy and safety.

Process instrumentation is vital for monitoring and controlling key variables like temperature, pressure, and flow, ensuring the efficient and safe operation of power plants. These instruments help optimize energy production, reduce downtime, and maintain regulatory compliance.

The pulp and paper industry depends on process instrumentation to control variables like temperature, pressure, and chemical concentrations. This ensures consistent product quality and optimized production efficiency, reducing waste and enhancing output.

Universities, especially those with research and laboratory facilities, rely on process instrumentation for precise monitoring and control. Instruments such as temperature sensors, pressure gauges, and flow meters support cutting-edge research by ensuring experimental accuracy and safety.

Water and wastewater treatment facilities rely on precise process instrumentation to monitor and control treatment processes. Instruments like flow meters, level sensors, and pressure gauges are vital for ensuring water is treated effectively and systems operate efficiently, meeting regulatory standards.