- Serving Maryland, DC, Virginia, Pennsylvania, & Delaware

- 800-230-4285

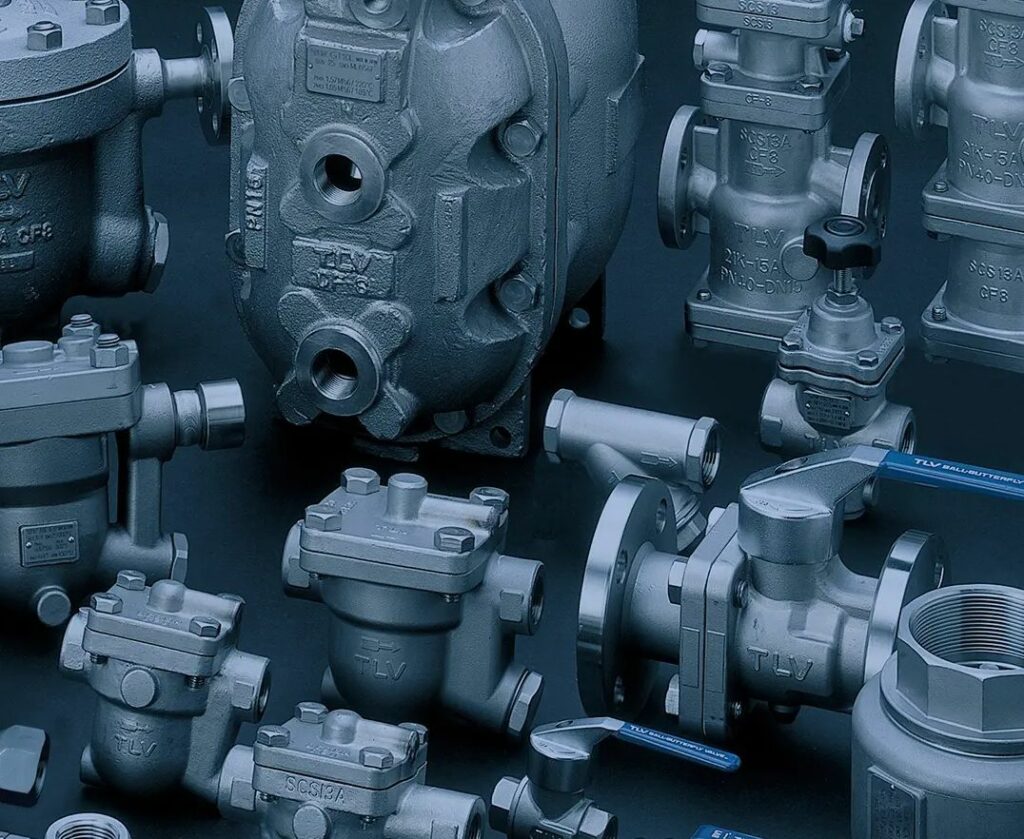

Steam traps play a crucial role in maintaining the efficiency of steam systems by removing condensate, air, and other gases without losing valuable steam. However, faulty steam traps can lead to energy loss, equipment damage, and decreased system performance. This article will guide you through identifying common steam trap issues and troubleshooting them to keep your system running efficiently.

Symptoms:

Possible Causes:

Solution:

Symptoms:

Possible Causes:

Solution:

Symptoms:

Possible Causes:

Solution:

Symptoms:

Possible Causes:

Solution:

Conduct Regular Inspections: Check steam traps quarterly or biannually to identify potential failures before they escalate.

Use a Steam Trap Testing Device: Utilize ultrasonic or infrared steam trap testing tools to detect leaks and operational issues.

Clean Strainers and Drain Lines: Regularly remove dirt and debris to prevent blockages that cause system inefficiencies.

Monitor Energy Usage: Unusual spikes in steam consumption may indicate a leaking or failed steam trap.

Proper steam trap maintenance is essential for maximizing energy efficiency, reducing costs, and ensuring the longevity of steam systems. By understanding common issues and troubleshooting them effectively, facility managers can prevent downtime and maintain peak operational performance.

If you’re looking for reliable steam trap solutions and expert guidance, CVL Technical Sales offers top-quality steam management products and support tailored to your industrial needs. Contact us today to learn more!